How Quartz Countertops Are Made

At the heart of quintessential home décor lies a vast variety of stunning countertops. From granite, marble, quartz, to quartzite, the options are almost endless. However, while all these options beautifully complement our kitchens, showers, and outdoor spaces, the creation process of each material differs vastly. As a leading supplier of natural stone countertops, we wish to enlighten you on the quartz countertop production process while also sharing our views on the controversial status of quartz countertops in the global market.

Quartz countertops, unlike granite or marble, aren’t entirely a product of nature. Named after a natural mineral, it’s a man-made stone formed through a meticulous and complex process. More than 90% of the quartz countertop comprises crushed quartz mixed with resin to bind it together, along with pigments for color and sometimes small amounts of glass or metallic flecks to add variety and sparkle.

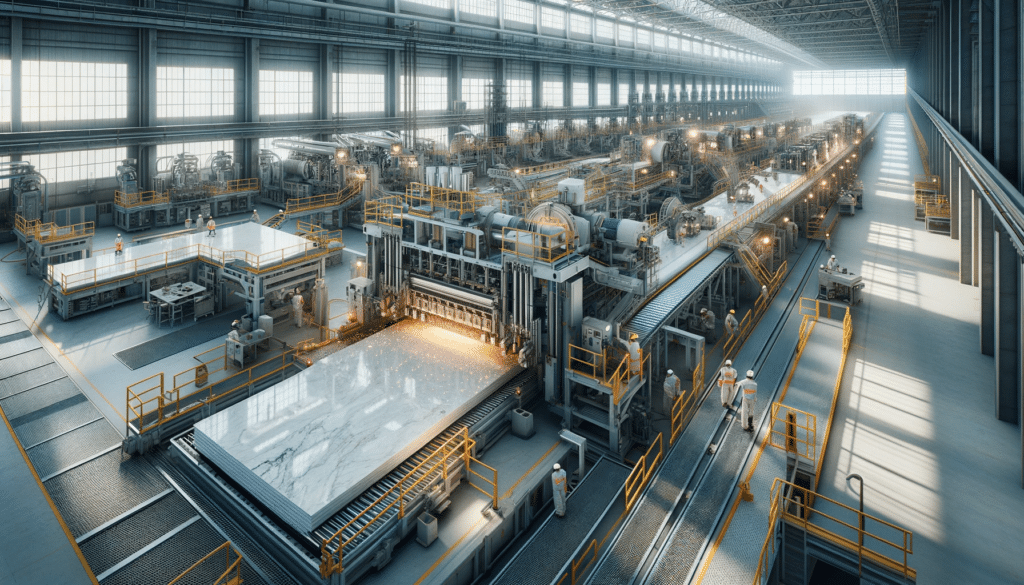

Quartz Countertop Production Process

The production process of engineered stone, or the method used to make them, starts with mining the crystals from the earth. These raw materials are then ground into an aggregate or powder form. The powder is blended with a high-strength polymer resin binder that holds the particles together and with pigment to give the countertop its color.

Molding and Curing

Following this, the blended material is poured into a mold to create slabs of the desired size. Using a method known as vibrocompaction, which uses vibration and pressure, the particles are tightly bound together, creating an incredibly dense product virtually impervious to stains, scratches, and heat. The slabs are then heated to cure and harden them.

Finishing Touches

Once cured, these slabs undergo a series of polishing for a lustrous finish, giving the countertops the shine and smoothness we adore. Finally, the slabs are inspected for quality before they are shipped to our facilities, ready to be custom-cut and installed in your homes.

Quartz Countertops Controversy

Recently, these man-made countertops have caused some stir due to concerns over their toxic nature. This has led to a ban in Australia, with other countries considering similar measures. It is worth noting that while we continue to offer this product, we encourage our customers to consider natural stone alternatives like granite, marble, and quartzite, which are not only safe but offer unique patterns and unparalleled resilience.

FAQ

The production consists of mining crystals, grinding them into a powder, blending them with a resin binder and color pigment, forming them into slabs, curing and then polishing the slabs.

Quartz countertops are made from crushed quartz crystals, which are mixed with a resin binder and pigment. This mixture is then formed into slabs, cured for hardness, and polished for a smooth finish.

Fabricating quartz countertops involves mining raw crystal, grinding it into a powder, mixing it with resin and color pigment, forming slabs, and then curing and polishing them.

The material is manufactured by combining the crushed mineral with a resin binder and pigment, forming this mixture into slabs, and then curing and polishing the slabs.

The steps to create quartz countertops include mining the mineral, grinding it into a powder, mixing it with a binder and pigment, forming this mixture into slabs, curing the slabs, and then polishing for a finish.